Xact EMS delivers tailored solutions to meet the precise needs of manufacturers, offering custom converting services using advanced equipment and deep application expertise. Whether it’s die-cutting, laminating, slitting, or kiss-cutting, we specialize in transforming high-performance materials into ready-to-use, application-specific components that enhance product reliability, efficiency, and performance.

From material selection to custom conversion, we’re your trusted source for engineered materials solutions—delivering precision, performance, and speed to every project.

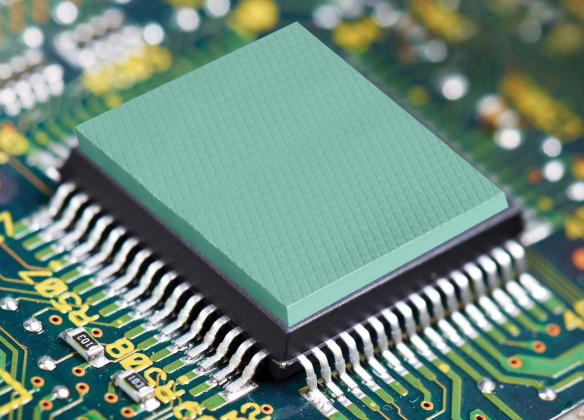

THERM-A-GAP PAD 60

| THERM-A-GAP PAD 60 Thermally Conductive Gap Filler Pads | ||||

|---|---|---|---|---|

| Products | Material Thickness | Carrier Type | Shape | Size |

| 61-04-1015-PAD60 | 0.04 in (1.01 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-04-CUSTOM-PAD60 | 0.04 in (1.01 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-05-1015-PAD60 | 0.05 in (1.27 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-05-CUSTOM-PAD60 | 0.05 in (1.27 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-06-1015-PAD60 | 0.06 in (1.52 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-06-CUSTOM-PAD60 | 0.06 in (1.52 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-07-1015-PAD60 | 0.07 in (1.78 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-07-CUSTOM-PAD60 | 0.07 in (1.78 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-08-1015-PAD60 | 0.08 in (2.03 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-08-CUSTOM-PAD60 | 0.08 in (2.03 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-09-1015-PAD60 | 0.09 in (2.29 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-09-CUSTOM-PAD60 | 0.09 in (2.29 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-10-1015-PAD60 | 0.10 in (2.54 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-10-CUSTOM-PAD60 | 0.10 in (2.54 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-11-1015-PAD60 | 0.11 in (2.79 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-11-CUSTOM-PAD60 | 0.11 in (2.79 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-12-1015-PAD60 | 0.12 in (3.05 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-12-CUSTOM-PAD60 | 0.12 in (3.05 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-13-1015-PAD60 | 0.13 in (3.30 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-13-CUSTOM-PAD60 | 0.13 in (3.30 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-14-1015-PAD60 | 0.14 in (3.56 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-14-CUSTOM-PAD60 | 0.14 in (3.56 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-15-1015-PAD60 | 0.15 in (3.81 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-15-CUSTOM-PAD60 | 0.15 in (3.81 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-16-1015-PAD60 | 0.16 in (4.06 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-16-CUSTOM-PAD60 | 0.16 in (4.06 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-17-1015-PAD60 | 0.17 in (4.32 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-17-CUSTOM-PAD60 | 0.17 in (4.32 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-18-1015-PAD60 | 0.18 in (4.57 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-18-CUSTOM-PAD60 | 0.18 in (4.57 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-19-1015-PAD60 | 0.19 in (4.83 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-19-CUSTOM-PAD60 | 0.19 in (4.83 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-20-1015-PAD60 | 0.20 in (5.08 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-20-CUSTOM-PAD60 | 0.20 in (5.08 mm) | No Carrier (Unsupported) | Custom | Custom |

| 62-02-1015-PAD60A | 0.02 in (0.508 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-03-1015-PAD60A | 0.03 in (0.762 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-04-1015-PAD60A | 0.04 in (1.01 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-04-CUSTOM-PAD60A | 0.04 in (1.01 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-05-1015-PAD60A | 0.05 in (1.27 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-05-CUSTOM-PAD60A | 0.05 in (1.27 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-06-1015-PAD60A | 0.06 in (1.52 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-06-CUSTOM-PAD60A | 0.06 in (1.52 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-07-1015-PAD60A | 0.07 in (1.78 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-07-CUSTOM-PAD60A | 0.07 in (1.78 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-08-1015-PAD60A | 0.08 in (2.03 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-08-CUSTOM-PAD60A | 0.08 in (2.03 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-09-1015-PAD60A | 0.09 in (2.29 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-09-CUSTOM-PAD60A | 0.09 in (2.29 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-10-1015-PAD60A | 0.10 in (2.54 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-10-CUSTOM-PAD60A | 0.10 in (2.54 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-11-1015-PAD60A | 0.11 in (2.79 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-11-CUSTOM-PAD60A | 0.11 in (2.79 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-12-1015-PAD60A | 0.12 in (3.05 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-12-CUSTOM-PAD60A | 0.12 in (3.05 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-13-1015-PAD60A | 0.13 in (3.30 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-13-CUSTOM-PAD60A | 0.13 in (3.30 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-14-1015-PAD60A | 0.14 in (3.56 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-14-CUSTOM-PAD60A | 0.14 in (3.56 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-15-1015-PAD60A | 0.15 in (3.81 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-15-CUSTOM-PAD60A | 0.15 in (3.81 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-16-1015-PAD60A | 0.16 in (4.06 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-16-CUSTOM-PAD60A | 0.16 in (4.06 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-17-1015-PAD60A | 0.17 in (4.32 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-17-CUSTOM-PAD60A | 0.17 in (4.32 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-18-1015-PAD60A | 0.18 in (4.57 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-18-CUSTOM-PAD60A | 0.18 in (4.57 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-19-1015-PAD60A | 0.19 in (4.83 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-19-CUSTOM-PAD60A | 0.19 in (4.83 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-20-1015-PAD60A | 0.20 in (5.08 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-20-CUSTOM-PAD60A | 0.20 in (5.08 mm) | A – Aluminum Foil with PSA | Custom | Custom |

THERM-A-GAP 579

| THERM-A-GAP PAD 80 Thermally Conductive Gap Filler Pads | ||||

|---|---|---|---|---|

| Products | Material Thickness | Carrier Type | Size | |

| 61-02-0909-G579 | 0.02 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-03-0909-G579 | 0.03 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-04-0909-G579 | 0.04 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-05-0909-G579 | 0.05 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-06-0909-G579 | 0.06 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-07-0909-G579 | 0.07 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-08-0909-G579 | 0.08 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-10-0909-G579 | 0.1 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-12-0909-G579 | 0.12 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-13-0909-G579 | 0.13 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-14-0909-G579 | 0.14 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-15-0909-G579 | 0.15 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-16-0909-G579 | 0.16 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-18-0909-G579 | 0.18 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-20-0909-G579 | 0.2 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 62-01-0909-A579 | 0.01 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-02-0909-A579 | 0.02 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-03-0909-A579 | 0.03 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-04-0909-A579 | 0.04 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-05-0909-A579 | 0.05 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-06-0909-A579 | 0.06 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-07-0909-A579 | 0.07 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-08-0909-A579 | 0.08 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-10-0909-A579 | 0.1 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-12-0909-A579 | 0.12 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-13-0909-A579 | 0.13 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-14-0909-A579 | 0.14 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-15-0909-A579 | 0.15 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-16-0909-A579 | 0.16 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-18-0909-A579 | 0.18 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-20-0909-A579 | 0.2 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 69-11-28540-G579 | 0.015 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-28539-G579 | 0.01 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20698-G579 | 0.02 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20913-G579 | 0.03 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20684-G579 | 0.04 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27395-G579 | 0.05 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20991-G579 | 0.06 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20685-G579 | 0.07 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-21259-G579 | 0.08 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20672-G579 | 0.1 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27102-G579 | 0.12 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20675-G579 | 0.13 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27100-G579 | 0.14 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27101-G579 | 0.15 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20686-G579 | 0.16 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27103-G579 | 0.18 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20687-G579 | 0.2 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-12-28540-A579 | 0.015 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-28539-A579 | 0.01 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20698-A579 | 0.02 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20913-A579 | 0.03 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20684-A579 | 0.04 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27395-A579 | 0.05 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20991-A579 | 0.06 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20685-A579 | 0.07 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-21259-A579 | 0.08 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20672-A579 | 0.1 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27102-A579 | 0.12 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20675-A579 | 0.13 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27100-A579 | 0.14 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27101-A579 | 0.15 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20686-A579 | 0.16 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27103-A579 | 0.18 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20687-A579 | 0.2 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 61-01-0909-579KT | 0.01 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-02-0909-579KT | 0.02 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-03-0909-579KT | 0.03 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-04-0909-579KT | 0.04 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-05-0909-579KT | 0.05 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-06-0909-579KT | 0.06 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-07-0909-579KT | 0.07 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-08-0909-579KT | 0.08 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-10-0909-579KT | 0.1 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-12-0909-579KT | 0.12 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-13-0909-579KT | 0.13 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-14-0909-579KT | 0.14 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-15-0909-579KT | 0.15 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-16-0909-579KT | 0.16 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-18-0909-579KT | 0.18 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 61-20-0909-579KT | 0.2 in | KT – Thermally Enhanced Polyimide | 9″ x 9″ | |

| 69-11-28540-579KT | 0.015 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-28539-579KT | 0.01 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20698-579KT | 0.02 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20913-579KT | 0.03 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20684-579KT | 0.04 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-27395-579KT | 0.05 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20991-579KT | 0.06 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20685-579KT | 0.07 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-21259-579KT | 0.08 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20672-579KT | 0.1 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-27102-579KT | 0.12 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20675-579KT | 0.13 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-27100-579KT | 0.14 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-27101-579KT | 0.15 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20686-579KT | 0.16 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-27103-579KT | 0.18 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 69-11-20687-579KT | 0.2 in | KT – Thermally Enhanced Polyimide | 18″ x 18″ | |

| 61-12-0909-579 | 0.12 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 61-13-0909-579 | 0.13 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 61-14-0909-579 | 0.14 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 61-15-0909-579 | 0.15 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 61-16-0909-579 | 0.16 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 61-18-0909-579 | 0.18 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 61-20-0909-579 | 0.2 in | No Carrier (Unsupported) | 9″ x 9″ | |

| 69-11-28540-579 | 0.015 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-27102-579 | 0.12 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-20675-579 | 0.13 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-27100-579 | 0.14 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-27101-579 | 0.15 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-20686-579 | 0.16 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-27103-579 | 0.18 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 69-11-20687-579 | 0.2 in | No Carrier (Unsupported) | 18″ x 18″ | |

| 61-14-0909-579PN | 0.14 in | PN – PEN Film | 9″ x 9″ | |

| 61-15-0909-579PN | 0.15 in | PN – PEN Film | 9″ x 9″ | |

| 61-16-0909-579PN | 0.16 in | PN – PEN Film | 9″ x 9″ | |

| 61-18-0909-579PN | 0.18 in | PN – PEN Film | 9″ x 9″ | |

| 61-20-0909-579PN | 0.2 in | PN – PEN Film | 9″ x 9″ | |

| 69-11-28540-579PN | 0.015 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-27102-579PN | 0.12 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-20675-579PN | 0.13 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-27100-579PN | 0.14 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-27101-579PN | 0.15 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-20686-579PN | 0.16 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-27103-579PN | 0.18 in | PN – PEN Film | 18″ x 18″ | |

| 69-11-20687-579PN | 0.2 in | PN – PEN Film | 18″ x 18″ | |

| 61-12-0909-579PN | 0.12 in | PN – PEN Film | 9″ x 9″ | |

| 61-13-0909-579PN | 0.13 in | PN – PEN Film | 9″ x 9″ | |

| CUSTOM-61-01-G579 | 0.01 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-02-G579 | 0.02 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-03-G579 | 0.03 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-04-G579 | 0.04 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-05-G579 | 0.05 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-06-G579 | 0.06 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-07-G579 | 0.07 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-08-G579 | 0.08 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-10-G579 | 0.1 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-12-G579 | 0.12 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-13-G579 | 0.13 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-14-G579 | 0.14 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-15-G579 | 0.15 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-16-G579 | 0.16 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-18-G579 | 0.18 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-20-G579 | 0.2 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-62-01-A579 | 0.01 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-02-A579 | 0.02 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-03-A579 | 0.03 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-04-A579 | 0.04 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-05-A579 | 0.05 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-06-A579 | 0.06 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-07-A579 | 0.07 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-08-A579 | 0.08 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-10-A579 | 0.1 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-12-A579 | 0.12 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-13-A579 | 0.13 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-14-A579 | 0.14 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-15-A579 | 0.15 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-16-A579 | 0.16 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-18-A579 | 0.18 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-20-A579 | 0.2 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-61-01-579KT | 0.01 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-02-579KT | 0.02 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-03-579KT | 0.03 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-04-579KT | 0.04 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-05-579KT | 0.05 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-06-579KT | 0.06 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-07-579KT | 0.07 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-08-579KT | 0.08 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-10-579KT | 0.1 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-12-579KT | 0.12 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-13-579KT | 0.13 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-14-579KT | 0.14 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-15-579KT | 0.15 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-16-579KT | 0.16 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-18-579KT | 0.18 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-20-579KT | 0.2 in | KT – Thermally Enhanced Polyimide | Custom | |

| CUSTOM-61-12-579 | 0.12 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-13-579 | 0.13 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-14-579 | 0.14 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-15-579 | 0.15 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-16-579 | 0.16 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-18-579 | 0.18 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-20-579 | 0.2 in | No Carrier (Unsupported) | Custom | |

| CUSTOM-61-12-579PN | 0.12 in | PN – PEN Film | Custom | |

| CUSTOM-61-13-579PN | 0.13 in | PN – PEN Film | Custom | |

| CUSTOM-61-14-579PN | 0.14 in | PN – PEN Film | Custom | |

| CUSTOM-61-15-579PN | 0.15 in | PN – PEN Film | Custom | |

| CUSTOM-61-16-579PN | 0.16 in | PN – PEN Film | Custom | |

| CUSTOM-61-18-579PN | 0.18 in | PN – PEN Film | Custom | |

| CUSTOM-61-20-579PN | 0.2 in | PN – PEN Film | Custom | |

THERM-A-GAP 570

| THERM-A-GAP PAD 570 Thermally Conductive Gap Filler Pads | ||||

|---|---|---|---|---|

| Products | Material Thickness | Carrier Type | Shape | |

| 62-02-0909-A570 | 0.02 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-03-0909-A570 | 0.03 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-04-0909-A570 | 0.04 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-05-0909-A570 | 0.05 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-06-0909-A570 | 0.06 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-07-0909-A570 | 0.07 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-08-0909-A570 | 0.08 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-10-0909-A570 | 0.1 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-12-0909-A570 | 0.12 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-13-0909-A570 | 0.13 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-14-0909-A570 | 0.14 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-15-0909-A570 | 0.15 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-16-0909-A570 | 0.16 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-18-0909-A570 | 0.18 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 62-20-0909-A570 | 0.2 in | A – Aluminum Foil with PSA | 9″ x 9″ | |

| 69-12-20698-A570 | 0.02 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20913-A570 | 0.03 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20684-A570 | 0.04 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27395-A570 | 0.05 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20991-A570 | 0.06 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20685-A570 | 0.07 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-21259-A570 | 0.08 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20672-A570 | 0.1 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27102-A570 | 0.12 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20675-A570 | 0.13 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27100-A570 | 0.14 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27101-A570 | 0.15 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20686-A570 | 0.16 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-27103-A570 | 0.18 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 69-12-20687-A570 | 0.2 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| 61-02-0909-G570 | 0.02 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-03-0909-G570 | 0.03 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-04-0909-G570 | 0.04 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-05-0909-G570 | 0.05 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-06-0909-G570 | 0.06 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-07-0909-G570 | 0.07 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-08-0909-G570 | 0.08 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-10-0909-G570 | 0.1 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-12-0909-G570 | 0.12 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-13-0909-G570 | 0.13 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-14-0909-G570 | 0.14 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-15-0909-G570 | 0.15 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-16-0909-G570 | 0.16 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-18-0909-G570 | 0.18 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 61-20-0909-G570 | 0.2 in | G – Woven Glass no PSA | 9″ x 9″ | |

| 69-11-20698-G570 | 0.02 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20913-G570 | 0.03 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20684-G570 | 0.04 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27395-G570 | 0.05 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20991-G570 | 0.06 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20685-G570 | 0.07 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-21259-G570 | 0.08 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20672-G570 | 0.1 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27102-G570 | 0.12 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20675-G570 | 0.13 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27100-G570 | 0.14 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27101-G570 | 0.15 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20686-G570 | 0.16 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-27103-G570 | 0.18 in | G – Woven Glass no PSA | 18″ x 18″ | |

| 69-11-20687-G570 | 0.2 in | G – Woven Glass no PSA | 18″ x 18″ | |

| CUSTOM-62-16-A570 | 0.16 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-18-A570 | 0.18 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-20-A570 | 0.2 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-61-02-G570 | 0.02 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-03-G570 | 0.03 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-04-G570 | 0.04 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-05-G570 | 0.05 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-06-G570 | 0.06 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-07-G570 | 0.07 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-08-G570 | 0.08 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-10-G570 | 0.1 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-12-G570 | 0.12 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-13-G570 | 0.13 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-14-G570 | 0.14 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-15-G570 | 0.15 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-16-G570 | 0.16 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-18-G570 | 0.18 in | G – Woven Glass no PSA | Custom | |

| CUSTOM-61-20-G570 | 0.2 in | G – Woven Glass no PSA | Custom | |

| 69-12-28540-A570 | 0.015 in | A – Aluminum Foil with PSA | 18″ x 18″ | |

| CUSTOM-62-02-A570 | 0.02 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-03-A570 | 0.03 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-04-A570 | 0.04 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-05-A570 | 0.05 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-06-A570 | 0.06 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-07-A570 | 0.07 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-08-A570 | 0.08 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-10-A570 | 0.1 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-12-A570 | 0.12 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-13-A570 | 0.13 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-14-A570 | 0.14 in | A – Aluminum Foil with PSA | Custom | |

| CUSTOM-62-15-A570 | 0.15 in | A – Aluminum Foil with PSA | Custom | |

THERM-A-GAP PAD 80

| THERM-A-GAP PAD 80 Thermally Conductive Gap Filler Pads | ||||

|---|---|---|---|---|

| Products | Material Thickness | Carrier Type | Shape | Size |

| 61-03-1015-PAD80A | 0.03 in (0.76 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-04-1015-PAD80 | 0.04 in (1.02 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-04-1015-PAD80A | 0.04 in (1.02 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-04-1015-PAD80G | 0.04 in (1.02 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-05-1015-PAD80 | 0.05 in (1.27 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-05-1015-PAD80A | 0.05 in (1.27 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-05-1015-PAD80G | 0.05 in (1.27 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-06-1015-PAD80 | 0.06 in (1.52 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-06-1015-PAD80A | 0.06 in (1.52 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-06-1015-PAD80G | 0.06 in (1.52 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-07-1015-PAD80 | 0.07 in (1.78 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-07-1015-PAD80A | 0.07 in (1.78 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-07-1015-PAD80G | 0.07 in (1.78 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-08-1015-PAD80 | 0.08 in (2.03 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-08-1015-PAD80A | 0.08 in (2.03 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-08-1015-PAD80G | 0.08 in (2.03 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-09-1015-PAD80 | 0.09 in (2.29 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-09-1015-PAD80A | 0.09 in (2.29 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-09-1015-PAD80G | 0.09 in (2.29 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-10-1015-PAD80 | 0.10 in (2.54 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-10-1015-PAD80A | 0.10 in (2.54 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-10-1015-PAD80G | 0.10 in (2.54 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-11-1015-PAD80 | 0.11 in (2.79 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-11-1015-PAD80A | 0.11 in (2.79 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-11-1015-PAD80G | 0.11 in (2.79 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-12-1015-PAD80 | 0.12 in (3.05 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-12-1015-PAD80A | 0.12 in (3.05 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-12-1015-PAD80G | 0.12 in (3.05 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-13-1015-PAD80 | 0.13 in (3.30 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-13-1015-PAD80A | 0.13 in (3.30 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-13-1015-PAD80G | 0.13 in (3.30 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-14-1015-PAD80 | 0.14 in (3.56 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-14-1015-PAD80A | 0.14 in (3.56 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-14-1015-PAD80G | 0.14 in (3.56 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-15-1015-PAD80 | 0.15 in (3.81 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-15-1015-PAD80A | 0.15 in (3.81 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-15-1015-PAD80G | 0.15 in (3.81 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-16-1015-PAD80 | 0.16 in (4.06 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-16-1015-PAD80A | 0.16 in (4.06 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-16-1015-PAD80G | 0.16 in (4.06 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-17-1015-PAD80 | 0.17 in (4.32 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-17-1015-PAD80A | 0.17 in (4.32 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-17-1015-PAD80G | 0.17 in (4.32 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-18-1015-PAD80 | 0.18 in (4.57 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-18-1015-PAD80A | 0.18 in (4.57 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-18-1015-PAD80G | 0.18 in (4.57 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-19-1015-PAD80 | 0.19 in (4.83 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-19-1015-PAD80A | 0.19 in (4.83 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-19-1015-PAD80G | 0.19 in (4.83 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-20-1015-PAD80 | 0.20 in (5.08 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-20-1015-PAD80A | 0.20 in (5.08 mm) | A – Aluminum Foil without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-20-1015-PAD80G | 0.20 in (5.08 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-03-1015-PAD80A | 0.03 in (0.76 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-04-1015-PAD80A | 0.04 in (1.02 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-05-1015-PAD80A | 0.05 in (1.27 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-06-1015-PAD80A | 0.06 in (1.52 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-07-1015-PAD80A | 0.07 in (1.78 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-08-1015-PAD80A | 0.08 in (2.03 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-09-1015-PAD80A | 0.09 in (2.29 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-10-1015-PAD80A | 0.10 in (2.54 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-11-1015-PAD80A | 0.11 in (2.79 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-12-1015-PAD80A | 0.12 in (3.05 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-13-1015-PAD80A | 0.13 in (3.30 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-14-1015-PAD80A | 0.14 in (3.56 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-15-1015-PAD80A | 0.15 in (3.81 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-16-1015-PAD80A | 0.16 in (4.06 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-17-1015-PAD80A | 0.17 in (4.32 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-18-1015-PAD80A | 0.18 in (4.57 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-19-1015-PAD80A | 0.19 in (4.83 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-20-1015-PAD80A | 0.20 in (5.08 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-02-1015-PAD80G | 0.02 in (0.51 mm) | G – Woven glass without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-03-1015-PAD80PN | 0.03 in (0.76 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-04-1015-PAD80PN | 0.04 in (1.02 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-05-1015-PAD80PN | 0.05 in (1.27 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-06-1015-PAD80PN | 0.06 in (1.52 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-07-1015-PAD80PN | 0.07 in (1.78 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-08-1015-PAD80PN | 0.08 in (2.03 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-09-1015-PAD80PN | 0.09 in (2.29 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-10-1015-PAD80PN | 0.10 in (2.54 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-11-1015-PAD80PN | 0.11 in (2.79 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-12-1015-PAD80PN | 0.12 in (3.05 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-13-1015-PAD80PN | 0.13 in (3.30 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-14-1015-PAD80PN | 0.14 in (3.56 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-15-1015-PAD80PN | 0.15 in (3.81 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-16-1015-PAD80PN | 0.16 in (4.06 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-17-1015-PAD80PN | 0.17 in (4.32 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-18-1015-PAD80PN | 0.18 in (4.57 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-19-1015-PAD80PN | 0.19 in (4.83 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-20-1015-PAD80PN | 0.20 in (5.08 mm) | PN – PN Film without PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

THERM-A-GAP 580

| THERM-A-GAP 580 Thermally Conductive Gap Filler Pads | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Products | Material Thickness | Carrier Type | Size | ||||||||

| 69-11-27100-G580 | 0.14 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-27101-G580 | 0.15 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20686-G580 | 0.16 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-27103-G580 | 0.18 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20687-G580 | 0.2 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 62-01-0909-A580 | 0.01 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-02-0909-A580 | 0.02 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-03-0909-A580 | 0.03 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-04-0909-A580 | 0.04 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-05-0909-A580 | 0.05 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-06-0909-A580 | 0.06 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-07-0909-A580 | 0.07 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-08-0909-A580 | 0.08 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-10-0909-A580 | 0.1 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-12-0909-A580 | 0.12 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-13-0909-A580 | 0.13 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-14-0909-A580 | 0.14 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-15-0909-A580 | 0.15 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-16-0909-A580 | 0.16 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-18-0909-A580 | 0.18 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 62-20-0909-A580 | 0.2 in | A – Aluminum Foil with PSA | 9″ x 9″ | ||||||||

| 69-12-28539-A580 | 0.01 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20698-A580 | 0.02 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20913-A580 | 0.03 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20684-A580 | 0.04 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-27395-A580 | 0.05 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20991-A580 | 0.06 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20685-A580 | 0.07 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-21259-A580 | 0.08 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20672-A580 | 0.1 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-27102-A580 | 0.12 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20675-A580 | 0.13 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-27100-A580 | 0.14 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-27101-A580 | 0.15 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20686-A580 | 0.16 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-27103-A580 | 0.18 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-12-20687-A580 | 0.2 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 61-01-0909-G580 | 0.01 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-02-0909-G580 | 0.02 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-03-0909-G580 | 0.03 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-04-0909-G580 | 0.04 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-05-0909-G580 | 0.05 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-06-0909-G580 | 0.06 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-07-0909-G580 | 0.07 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-08-0909-G580 | 0.08 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-09-0909-G580 | 0.09 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-10-0909-G580 | 0.1 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-11-0909-G580 | 0.11 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-12-0909-G580 | 0.12 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-13-0909-G580 | 0.13 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-14-0909-G580 | 0.14 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-15-0909-G580 | 0.15 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-16-0909-G580 | 0.16 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-17-0909-G580 | 0.17 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-18-0909-G580 | 0.18 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-19-0909-G580 | 0.19 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 61-20-0909-G580 | 0.2 in | G – Woven Glass no PSA | 9″ x 9″ | ||||||||

| 69-11-28540-G580 | 0.015 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-12-28540-A580 | 0.015 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-11-28539-G580 | 0.01 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20698-G580 | 0.02 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20913-G580 | 0.03 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20684-G580 | 0.04 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-27395-G580 | 0.05 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20991-G580 | 0.06 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20685-G580 | 0.07 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-21259-G580 | 0.08 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20672-G580 | 0.1 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-27102-G580 | 0.12 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-20675-G580 | 0.13 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-28540-G580 | 0.015 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-12-28540-A580 | 0.015 in | A – Aluminum Foil with PSA | 18″ x 18″ | ||||||||

| 69-11-28539-G580 | 0.01 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 62-01-0909-580 | 0.01 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-02-0909-580 | 0.02 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-03-0909-580 | 0.03 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-04-0909-580 | 0.04 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-05-0909-580 | 0.05 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-06-0909-580 | 0.06 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-07-0909-580 | 0.07 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-08-0909-580 | 0.08 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-10-0909-580 | 0.1 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-12-0909-580 | 0.12 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-13-0909-580 | 0.13 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-14-0909-580 | 0.14 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-15-0909-580 | 0.15 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-16-0909-580 | 0.16 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-18-0909-580 | 0.18 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 62-20-0909-580 | 0.2 in | No Carrier (Unsupported) | 9″ x 9″ | ||||||||

| 69-11-27100-G580 | 0.14 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-11-27101-G580 | 0.15 in | G – Woven Glass no PSA | 18″ x 18″ | ||||||||

| 69-12-28539-580 | 0.01 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20698-580 | 0.02 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20913-580 | 0.03 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20684-580 | 0.04 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-27395-580 | 0.05 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20991-580 | 0.06 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20685-580 | 0.07 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-21259-580 | 0.08 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20672-580 | 0.1 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-27102-580 | 0.12 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20675-580 | 0.13 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-27100-580 | 0.14 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-27101-580 | 0.15 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20686-580 | 0.16 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-27103-580 | 0.18 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| 69-12-20687-580 | 0.2 in | No Carrier (Unsupported) | 18″ x 18″ | ||||||||

| CUSTOM-62-01-A580 | 0.01 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-02-A580 | 0.02 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-03-A580 | 0.03 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-04-A580 | 0.04 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-05-A580 | 0.05 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-06-A580 | 0.06 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-07-A580 | 0.07 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-08-A580 | 0.08 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-10-A580 | 0.1 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-12-A580 | 0.12 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-13-A580 | 0.13 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-14-A580 | 0.14 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-15-A580 | 0.15 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-16-A580 | 0.16 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-18-A580 | 0.18 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-20-A580 | 0.2 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-01-A580 | 0.01 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-02-A580 | 0.02 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-03-A580 | 0.03 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-04-A580 | 0.04 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-05-A580 | 0.05 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-06-A580 | 0.06 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-07-A580 | 0.07 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-08-A580 | 0.08 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-10-A580 | 0.1 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-12-A580 | 0.12 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-13-A580 | 0.13 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-14-A580 | 0.14 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-15-A580 | 0.15 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-16-A580 | 0.16 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-18-A580 | 0.18 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-20-A580 | 0.2 in | A – Aluminum Foil with PSA | Custom | ||||||||

| CUSTOM-62-01-G580 | 0.01 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-02-G580 | 0.02 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-03-G580 | 0.03 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-04-G580 | 0.04 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-05-G580 | 0.05 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-06-G580 | 0.06 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-07-G580 | 0.07 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-08-G580 | 0.08 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-10-G580 | 0.1 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-12-G580 | 0.12 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-13-G580 | 0.13 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-14-G580 | 0.14 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-15-G580 | 0.15 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-16-G580 | 0.16 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-18-G580 | 0.18 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-20-G580 | 0.2 in | G – Woven Glass no PSA | Custom | ||||||||

| CUSTOM-62-01-580 | 0.01 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-02-580 | 0.02 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-03-580 | 0.03 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-04-580 | 0.04 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-05-580 | 0.05 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-06-580 | 0.06 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-07-580 | 0.07 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-08-580 | 0.08 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-10-580 | 0.1 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-12-580 | 0.12 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-13-580 | 0.13 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-14-580 | 0.14 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-15-580 | 0.15 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-16-580 | 0.16 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-18-580 | 0.18 in | No Carrier (Unsupported) | Custom | ||||||||

| CUSTOM-62-20-580 | 0.2 in | No Carrier (Unsupported) | Custom | ||||||||

THERM-A-GAP PAD 70TP

| THERM-A-GAP PAD 70TP Thermally Conductive Gap Filler Pads | ||||

|---|---|---|---|---|

| Products | Material Thickness | Carrier Type | Shape | Size |

| 61-03-1015-PAD70TP | 0.03 in (0.76 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-03-CUSTOM-PAD70TP | 0.03 in (0.76 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-04-1015-PAD70TP | 0.04 in (1.02 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-04-CUSTOM-PAD70TP | 0.04 in (1.02 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-05-1015-PAD70TP | 0.05 in (1.27 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-05-CUSTOM-PAD70TP | 0.05 in (1.27 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-06-1015-PAD70TP | 0.06 in (1.52 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-06-CUSTOM-PAD70TP | 0.06 in (1.52 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-07-1015-PAD70TP | 0.07 in (1.78 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-07-CUSTOM-PAD70TP | 0.07 in (1.78 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-08-1015-PAD70TP | 0.08 in (2.03 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-08-CUSTOM-PAD70TP | 0.08 in (2.03 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-09-1015-PAD70TP | 0.09 in (2.29 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-09-CUSTOM-PAD70TP | 0.09 in (2.29 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-10-1015-PAD70TP | 0.10 in (2.54 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-10-CUSTOM-PAD70TP | 0.10 in (2.54 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-11-1015-PAD70TP | 0.11 in (2.79 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-11-CUSTOM-PAD70TP | 0.11 in (2.79 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-12-1015-PAD70TP | 0.12 in (3.05 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-12-CUSTOM-PAD70TP | 0.12 in (3.05 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-13-1015-PAD70TP | 0.13 in (3.30 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-13-CUSTOM-PAD70TP | 0.13 in (3.30 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-14-1015-PAD70TP | 0.14 in (3.56 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-14-CUSTOM-PAD70TP | 0.14 in (3.56 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-15-1015-PAD70TP | 0.15 in (3.81 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-15-CUSTOM-PAD70TP | 0.15 in (3.81 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-16-1015-PAD70TP | 0.16 in (4.06 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-16-CUSTOM-PAD70TP | 0.16 in (4.06 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-17-1015-PAD70TP | 0.17 in (4.32 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-17-CUSTOM-PAD70TP | 0.17 in (4.32 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-18-1015-PAD70TP | 0.18 in (4.57 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-18-CUSTOM-PAD70TP | 0.18 in (4.57 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-19-1015-PAD70TP | 0.19 in (4.83 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-19-CUSTOM-PAD70TP | 0.19 in (4.83 mm) | No Carrier (Unsupported) | Custom | Custom |

| 61-20-1015-PAD70TP | 0.20 in (5.08 mm) | No Carrier (Unsupported) | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 61-20-CUSTOM-PAD70TP | 0.20 in (5.08 mm) | No Carrier (Unsupported) | Custom | Custom |

| 62-03-1015-PAD70TPA | 0.03 in (0.76 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-03-1015-PAD70TPG | 0.03 in (0.76 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-03-CUSTOM-PAD70TPA | 0.03 in (0.76 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-03-CUSTOM-PAD70TPG | 0.03 in (0.76 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-04-1015-PAD70TPA | 0.04 in (1.02 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-04-1015-PAD70TPG | 0.04 in (1.02 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-04-CUSTOM-PAD70TPA | 0.04 in (1.02 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-04-CUSTOM-PAD70TPG | 0.04 in (1.02 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-05-1015-PAD70TPA | 0.05 in (1.27 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-05-1015-PAD70TPG | 0.05 in (1.27 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-05-CUSTOM-PAD70TPA | 0.05 in (1.27 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-05-CUSTOM-PAD70TPG | 0.05 in (1.27 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-06-1015-PAD70TPA | 0.06 in (1.52 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-06-1015-PAD70TPG | 0.06 in (1.52 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-06-CUSTOM-PAD70TPA | 0.06 in (1.52 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-06-CUSTOM-PAD70TPG | 0.06 in (1.52 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-07-1015-PAD70TPA | 0.07 in (1.78 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-07-1015-PAD70TPG | 0.07 in (1.78 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-07-CUSTOM-PAD70TPA | 0.07 in (1.78 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-07-CUSTOM-PAD70TPG | 0.07 in (1.78 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-08-1015-PAD70TPA | 0.08 in (2.03 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-08-1015-PAD70TPG | 0.08 in (2.03 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-08-CUSTOM-PAD70TPA | 0.08 in (2.03 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-08-CUSTOM-PAD70TPG | 0.08 in (2.03 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-09-1015-PAD70TPA | 0.09 in (2.29 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-09-1015-PAD70TPG | 0.09 in (2.29 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-09-CUSTOM-PAD70TPA | 0.09 in (2.29 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-09-CUSTOM-PAD70TPG | 0.09 in (2.29 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-10-1015-PAD70TPA | 0.10 in (2.54 mm) | Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-10-1015-PAD70TPG | 0.10 in (2.54 mm) | Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-10-CUSTOM-PAD70TPA | 0.10 in (2.54 mm) | Aluminum Foil with PSA | Custom | Custom |

| 62-10-CUSTOM-PAD70TPG | 0.10 in (2.54 mm) | Fiberglass with PSA | Custom | Custom |

| 62-11-1015-PAD70TPA | 0.11 in (2.79 mm) | Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-11-1015-PAD70TPG | 0.11 in (2.79 mm) | Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-11-CUSTOM-PAD70TPA | 0.11 in (2.79 mm) | Aluminum Foil with PSA | Custom | Custom |

| 62-11-CUSTOM-PAD70TPG | 0.11 in (2.79 mm) | Fiberglass with PSA | Custom | Custom |

| 62-10-1015-PAD70TPA | 0.10 in (2.54 mm) | Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-10-1015-PAD70TPG | 0.10 in (2.54 mm) | Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-10-CUSTOM-PAD70TPA | 0.10 in (2.54 mm) | Aluminum Foil with PSA | Custom | Custom |

| 62-10-CUSTOM-PAD70TPG | 0.10 in (2.54 mm) | Fiberglass with PSA | Custom | Custom |

| 62-12-1015-PAD70TPA | 0.12 in (3.05 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-12-1015-PAD70TPG | 0.12 in (3.05 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-12-CUSTOM-PAD70TPA | 0.12 in (3.05 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-12-CUSTOM-PAD70TPG | 0.12 in (3.05 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-13-1015-PAD70TPA | 0.13 in (3.30 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-13-1015-PAD70TPG | 0.13 in (3.30 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-13-CUSTOM-PAD70TPA | 0.13 in (3.30 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-13-CUSTOM-PAD70TPG | 0.13 in (3.30 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-14-1015-PAD70TPA | 0.14 in (3.56 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-14-1015-PAD70TPG | 0.14 in (3.56 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-14-CUSTOM-PAD70TPA | 0.14 in (3.56 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-14-CUSTOM-PAD70TPG | 0.14 in (3.56 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-15-1015-PAD70TPA | 0.15 in (3.81 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-15-1015-PAD70TPG | 0.15 in (3.81 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-15-CUSTOM-PAD70TPA | 0.15 in (3.81 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-15-CUSTOM-PAD70TPG | 0.15 in (3.81 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-16-1015-PAD70TPA | 0.16 in (4.06 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-16-1015-PAD70TPG | 0.16 in (4.06 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-16-CUSTOM-PAD70TPA | 0.16 in (4.06 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-16-CUSTOM-PAD70TPG | 0.16 in (4.06 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-17-1015-PAD70TPA | 0.17 in (4.32 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-17-1015-PAD70TPG | 0.17 in (4.32 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-17-CUSTOM-PAD70TPA | 0.17 in (4.32 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-17-CUSTOM-PAD70TPG | 0.17 in (4.32 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-18-1015-PAD70TPA | 0.18 in (4.57 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-18-1015-PAD70TPG | 0.18 in (4.57 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-18-CUSTOM-PAD70TPA | 0.18 in (4.57 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-18-CUSTOM-PAD70TPG | 0.18 in (4.57 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-19-1015-PAD70TPA | 0.19 in (4.83 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-19-1015-PAD70TPG | 0.19 in (4.83 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-19-CUSTOM-PAD70TPA | 0.19 in (4.83 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-19-CUSTOM-PAD70TPG | 0.19 in (4.83 mm) | G – Fiberglass with PSA | Custom | Custom |

| 62-20-1015-PAD70TPA | 0.20 in (5.08 mm) | A – Aluminum Foil with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-20-1015-PAD70TPG | 0.20 in (5.08 mm) | G – Fiberglass with PSA | Flat sheets | 10 in x 15 in (254 mm x 381 mm) |

| 62-20-CUSTOM-PAD70TPA | 0.20 in (5.08 mm) | A – Aluminum Foil with PSA | Custom | Custom |

| 62-20-CUSTOM-PAD70TPG | 0.20 in (5.08 mm) | G – Fiberglass with PSA | Custom | Custom |

THERM-A-GAP PAD 30

| THERM-A-GAP PAD 30 Thermally Conductive Gap Filler Pads | |||

|---|---|---|---|

| Products | Material Thickness | Carrier Type | Size |

| 61-02-0909-PAD30 | 0.02 in (0.51 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-02-0909-PAD30G | 0.02 in (0.51 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-02-0909-PAD30KT | 0.02 in (0.51 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-02-0909-PAD30PN | 0.02 in (0.51 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-02-CUSTOM-PAD30G | 0.02 in (0.51 mm) | G – Woven Glass no PSA | Custom |

| 61-02-CUSTOM-PAD30KT | 0.02 in (0.51 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-02-CUSTOM-PAD30PN | 0.02 in (0.51 mm) | PN – PEN Film | Custom |

| 61-03-0909-PAD30 | 0.03 in (0.76 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-03-0909-PAD30G | 0.03 in (0.76 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-03-0909-PAD30KT | 0.03 in (0.76 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-03-0909-PAD30PN | 0.03 in (0.76 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-03-CUSTOM-PAD30G | 0.03 in (0.76 mm) | G – Woven Glass no PSA | Custom |

| 61-03-CUSTOM-PAD30KT | 0.03 in (0.76 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-03-CUSTOM-PAD30PN | 0.03 in (0.76 mm) | PN – PEN Film | Custom |

| 61-04-0909-PAD30 | 0.04 in (1.02 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-04-0909-PAD30G | 0.04 in (1.02 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-04-0909-PAD30KT | 0.04 in (1.02 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-04-0909-PAD30PN | 0.04 in (1.02 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-04-CUSTOM-PAD30 | 0.04 in (1.02 mm) | No Carrier (Unsupported) | Custom |

| 61-04-CUSTOM-PAD30G | 0.04 in (1.02 mm) | G – Woven Glass no PSA | Custom |

| 61-04-CUSTOM-PAD30KT | 0.04 in (1.02 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-04-CUSTOM-PAD30PN | 0.04 in (1.02 mm) | PN – PEN Film | Custom |

| 61-05-0909-PAD30 | 0.05 in (1.27 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-05-0909-PAD30G | 0.05 in (1.27 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-05-0909-PAD30KT | 0.05 in (1.27 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-05-0909-PAD30PN | 0.05 in (1.27 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-05-CUSTOM-PAD30 | 0.05 in (1.27 mm) | No Carrier (Unsupported) | Custom |

| 61-05-CUSTOM-PAD30G | 0.05 in (1.27 mm) | G – Woven Glass no PSA | Custom |

| 61-05-CUSTOM-PAD30KT | 0.05 in (1.27 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-05-CUSTOM-PAD30PN | 0.05 in (1.27 mm) | PN – PEN Film | Custom |

| 61-06-0909-PAD30 | 0.06 in (1.52 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-06-0909-PAD30G | 0.06 in (1.52 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-06-0909-PAD30KT | 0.06 in (1.52 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-06-0909-PAD30PN | 0.06 in (1.52 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-06-CUSTOM-PAD30 | 0.06 in (1.52 mm) | No Carrier (Unsupported) | Custom |

| 61-06-CUSTOM-PAD30G | 0.06 in (1.52 mm) | G – Woven Glass no PSA | Custom |

| 61-06-CUSTOM-PAD30KT | 0.06 in (1.52 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-06-CUSTOM-PAD30PN | 0.06 in (1.52 mm) | PN – PEN Film | Custom |

| 61-07-0909-PAD30 | 0.07 in (1.78 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-07-0909-PAD30G | 0.07 in (1.78 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-07-0909-PAD30KT | 0.07 in (1.78 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-07-0909-PAD30PN | 0.07 in (1.78 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-07-CUSTOM-PAD30 | 0.07 in (1.78 mm) | No Carrier (Unsupported) | Custom |

| 61-07-CUSTOM-PAD30G | 0.07 in (1.78 mm) | G – Woven Glass no PSA | Custom |

| 61-07-CUSTOM-PAD30KT | 0.07 in (1.78 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-07-CUSTOM-PAD30PN | 0.07 in (1.78 mm) | PN – PEN Film | Custom |

| 61-08-0909-PAD30 | 0.08 in (2.03 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-08-0909-PAD30G | 0.08 in (2.03 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-08-0909-PAD30KT | 0.08 in (2.03 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-08-0909-PAD30PN | 0.08 in (2.03 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-08-CUSTOM-PAD30 | 0.08 in (2.03 mm) | No Carrier (Unsupported) | Custom |

| 61-08-CUSTOM-PAD30G | 0.08 in (2.03 mm) | G – Woven Glass no PSA | Custom |

| 61-08-CUSTOM-PAD30KT | 0.08 in (2.03 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-08-CUSTOM-PAD30PN | 0.08 in (2.03 mm) | PN – PEN Film | Custom |

| 61-10-0909-PAD30 | 0.10 in (2.54 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-10-0909-PAD30G | 0.10 in (2.54 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-10-0909-PAD30KT | 0.10 in (2.54 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-10-0909-PAD30PN | 0.10 in (2.54 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-10-CUSTOM-PAD30 | 0.10 in (2.54 mm) | No Carrier (Unsupported) | Custom |

| 61-10-CUSTOM-PAD30G | 0.10 in (2.54 mm) | G – Woven Glass no PSA | Custom |

| 61-10-CUSTOM-PAD30KT | 0.10 in (2.54 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-10-CUSTOM-PAD30PN | 0.10 in (2.54 mm) | PN – PEN Film | Custom |

| 61-12-0909-PAD30 | 0.12 in (3.05 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-12-0909-PAD30G | 0.12 in (3.05 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-12-0909-PAD30KT | 0.12 in (3.05 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-12-0909-PAD30PN | 0.12 in (3.05 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-12-CUSTOM-PAD30 | 0.12 in (3.05 mm) | No Carrier (Unsupported) | Custom |

| 61-12-CUSTOM-PAD30G | 0.12 in (3.05 mm) | G – Woven Glass no PSA | Custom |

| 61-12-CUSTOM-PAD30KT | 0.12 in (3.05 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-12-CUSTOM-PAD30PN | 0.12 in (3.05 mm) | PN – PEN Film | Custom |

| 61-13-0909-PAD30 | 0.13 in (3.30 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-13-0909-PAD30G | 0.13 in (3.30 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-13-0909-PAD30KT | 0.13 in (3.30 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-13-0909-PAD30PN | 0.13 in (3.30 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-13-CUSTOM-PAD30 | 0.13 in (3.30 mm) | No Carrier (Unsupported) | Custom |

| 61-13-CUSTOM-PAD30G | 0.13 in (3.30 mm) | G – Woven Glass no PSA | Custom |

| 61-13-CUSTOM-PAD30KT | 0.13 in (3.30 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-13-CUSTOM-PAD30PN | 0.13 in (3.30 mm) | PN – PEN Film | Custom |

| 61-14-0909-PAD30 | 0.14 in (3.56 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-14-0909-PAD30G | 0.14 in (3.56 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-14-0909-PAD30KT | 0.14 in (3.56 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-14-0909-PAD30PN | 0.14 in (3.56 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-14-CUSTOM-PAD30 | 0.14 in (3.56 mm) | No Carrier (Unsupported) | Custom |

| 61-14-CUSTOM-PAD30G | 0.14 in (3.56 mm) | G – Woven Glass no PSA | Custom |

| 61-14-CUSTOM-PAD30KT | 0.14 in (3.56 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-14-CUSTOM-PAD30PN | 0.14 in (3.56 mm) | PN – PEN Film | Custom |

| 61-15-0909-PAD30 | 0.15 in (3.81 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-15-0909-PAD30G | 0.15 in (3.81 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-15-0909-PAD30KT | 0.15 in (3.81 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-15-0909-PAD30PN | 0.15 in (3.81 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-15-CUSTOM-PAD30 | 0.15 in (3.81 mm) | No Carrier (Unsupported) | Custom |

| 61-15-CUSTOM-PAD30G | 0.15 in (3.81 mm) | G – Woven Glass no PSA | Custom |

| 61-15-CUSTOM-PAD30KT | 0.15 in (3.81 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-15-CUSTOM-PAD30PN | 0.15 in (3.81 mm) | PN – PEN Film | Custom |

| 61-16-0909-PAD30 | 0.16 in (4.06 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-16-0909-PAD30G | 0.16 in (4.06 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-16-0909-PAD30KT | 0.16 in (4.06 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-16-0909-PAD30PN | 0.16 in (4.06 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-16-CUSTOM-PAD30 | 0.16 in (4.06 mm) | No Carrier (Unsupported) | Custom |

| 61-16-CUSTOM-PAD30G | 0.16 in (4.06 mm) | G – Woven Glass no PSA | Custom |

| 61-16-CUSTOM-PAD30KT | 0.16 in (4.06 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-16-CUSTOM-PAD30PN | 0.16 in (4.06 mm) | PN – PEN Film | Custom |

| 61-18-0909-PAD30 | 0.18 in (4.57 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-18-0909-PAD30G | 0.18 in (4.57 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-18-0909-PAD30KT | 0.18 in (4.57 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-18-0909-PAD30PN | 0.18 in (4.57 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-18-CUSTOM-PAD30 | 0.18 in (4.57 mm) | No Carrier (Unsupported) | Custom |

| 61-18-CUSTOM-PAD30G | 0.18 in (4.57 mm) | G – Woven Glass no PSA | Custom |

| 61-18-CUSTOM-PAD30KT | 0.18 in (4.57 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-18-CUSTOM-PAD30PN | 0.18 in (4.57 mm) | PN – PEN Film | Custom |

| 61-20-0909-PAD30 | 0.20 in (5.08 mm) | No Carrier (Unsupported) | 9 x 9 in (229 x 229 mm) |

| 61-20-0909-PAD30G | 0.20 in (5.08 mm) | G – Woven Glass no PSA | 9 x 9 in (229 x 229 mm) |

| 61-20-0909-PAD30KT | 0.20 in (5.08 mm) | KT – Thermally Enhanced Polyimide | 9 x 9 in (229 x 229 mm) |

| 61-20-0909-PAD30PN | 0.20 in (5.08 mm) | PN – PEN Film | 9 x 9 in (229 x 229 mm) |

| 61-20-CUSTOM-PAD30 | 0.20 in (5.08 mm) | No Carrier (Unsupported) | Custom |

| 61-20-CUSTOM-PAD30G | 0.20 in (5.08 mm) | G – Woven Glass no PSA | Custom |

| 61-20-CUSTOM-PAD30KT | 0.20 in (5.08 mm) | KT – Thermally Enhanced Polyimide | Custom |

| 61-20-CUSTOM-PAD30PN | 0.20 in (5.08 mm) | PN – PEN Film | Custom |