When it comes to complex electronic systems in aerospace, medical, industrial, and defense applications, precision-engineered cable assemblies are not optional—they’re mission critical.

At Xact, we don’t just build custom cable assemblies—we engineer them from the ground up with precision, reliability, and manufacturability in mind. Our end-to-end engineering support ensures your project starts with a solid design foundation and ends with a perfectly built solution, ready for the demands of your application.

Why Engineering-Driven Cable Assemblies Matter

Poorly specified cables or generic off-the-shelf assemblies can lead to EMI issues, signal degradation, premature wear, or failure in the field. That’s why Xact offers a deeply integrated engineering and manufacturing process to deliver solutions that perform.

We provide:

- Custom Electrical Schematics

- 2D Manufacturing Drawings

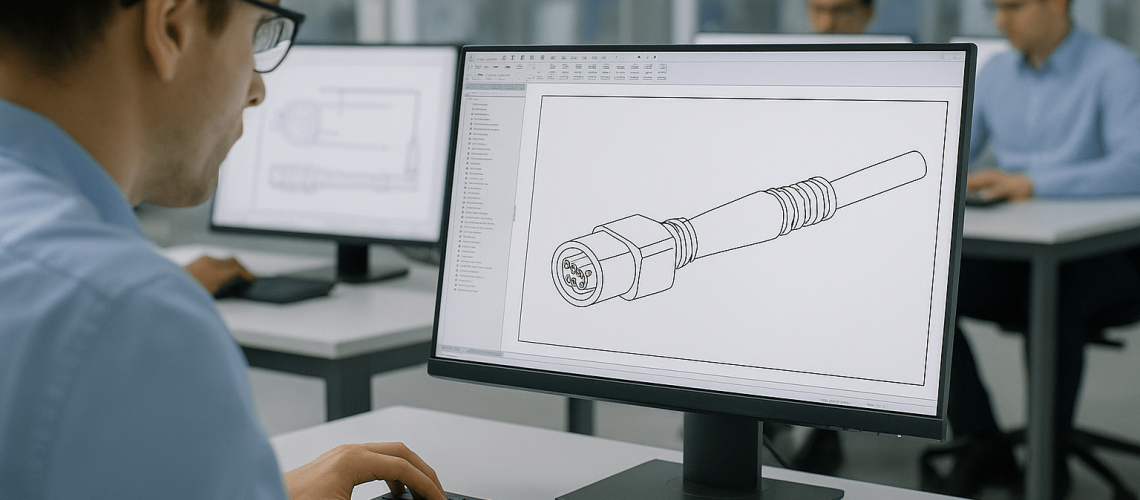

- 3D Cable Assembly Models

- Pinout Tables and Wire Maps

- Design-for-Manufacturability (DFM) Reviews

- Bill of Materials (BOM) Structuring

- Cable Routing and Connector Analysis

Whether you’re in the early stages of product development or optimizing a mature design, our engineering team helps you avoid costly revisions and ensures your design is ready for production and field deployment.

From Concept to Connector: Xact Engineering Services Include:

2D & 3D Drawings

We produce professional-grade 2D cable drawings for manufacturing and inspection, along with 3D models that integrate seamlessly into your mechanical assemblies.

These assets ensure:

- Precise cable routing in tight enclosures

- Proper strain relief and bend radius control

- Accurate mating to PCBs, sensors, backplanes, and more

Full Documentation Support

We help generate the documentation needed for your quality system, including:

- Full pinout tables

- Color-coded wiremaps

- Part numbering

- Revision control strategies

Engineering Integration

Our engineers collaborate with your team to define:

- Optimal connector types (mil/aero, commercial, industrial)

- Jacket materials and shielding strategies

- Labeling, overmolding, and strain relief requirements

- Routing and assembly best practices

Why Partner with Xact?

When you work with Xact, you get more than just cables—you get a team of electrical and mechanical engineers focused on manufacturability, signal integrity, and performance.

- 25+ Years of experience across aerospace, defense, medical, and industrial sectors

- ISO-certified processes and quality control

- Agile support from prototyping to volume production

- Transparent communication and free up-front drawings with every quote

Start with a Free Engineered Drawing

Ask us about a free engineered drawings specifically for your application. This drawing isn’t just a picture—it’s a manufacturing-grade document that supports your design process, documentation, and procurement team.